Hydraulic systems are vital for numerous industrial and mobile applications, using hydraulic fluid to efficiently transmit power. However, over time, this fluid can become contaminated with particles and debris, causing inefficiencies, component wear, and potentially catastrophic failures. Hydraulic filters are essential in preventing these issues by keeping the fluid clean and ensuring the system operates smoothly.

Understanding Hydraulic Filters

Hydraulic systems are crucial for many industrial and mobile applications, relying on hydraulic fluid to transmit power efficiently. However, this fluid can become contaminated with particles and debris over time, leading to inefficiencies, component wear, and even catastrophic failures. Hydraulic filters play an essential role in preventing these problems by keeping the fluid clean and ensuring smooth system operation.

Functions of Hydraulic Filters

The main role of hydraulic filters is to stop contaminants from circulating within the hydraulic system. These contaminants can cause abrasive wear on components, leading to decreased efficiency and potential breakdowns. Additionally, hydraulic filters preserve the purity of the hydraulic fluid, maintaining its viscosity and lubricating properties. By removing contaminants, hydraulic filters enhance the overall reliability and lifespan of hydraulic systems.

Types of Hydraulic Filters

Hydraulic filters come in various types and configurations, each suited to different applications and operating conditions. The most common types of hydraulic filters include:

In-Line Filters: These filters are installed directly in the hydraulic line and are often used in high-pressure applications. They typically consist of a housing with a replaceable filter element.

Suction Filters: Suction filters are placed inside the reservoir or hydraulic tank and are designed to remove contaminants from the fluid as it is drawn into the system's pump.

Return Line Filters: These filters are installed on the return line, filtering the hydraulic fluid as it returns to the reservoir. Return line filters are effective at capturing larger particles and preventing them from re-entering the system.

Pressure Filters: Pressure filters are installed in the hydraulic line and operate under pressure. They are designed to remove contaminants from the fluid while maintaining system pressure.

Off-Line Filters: Off-line filters are independent filtration units that can be connected to the hydraulic system for periodic or continuous filtration. They offer flexibility and convenience in maintaining system cleanliness.

Selecting the right type of hydraulic filter depends on factors such as flow rate, operating pressure, fluid viscosity, and the level of contamination in the system. Importance of Hydraulic Filter Maintenance Proper maintenance of hydraulic filters is essential for ensuring the continued effectiveness of the filtration system. Neglecting filter maintenance can lead to increased system downtime, reduced efficiency, and costly repairs.

Here are some key maintenance practices to keep your hydraulic filters in optimal condition:

Regular Inspections: Inspect hydraulic filters regularly for signs of damage, clogging, or contamination. Replace filters that show excessive wear or are no longer effective.

Scheduled Replacements: Follow the manufacturer's recommendations for replacing hydraulic filters at specified intervals. Regular filter replacements help prevent system contamination and maintain optimal performance.

Filter Element Upgrades: Consider upgrading to high-performance filter elements with finer filtration capabilities. These can provide enhanced protection against contaminants and extend the service life of your hydraulic system.

Proper Installation: Ensure that hydraulic filters are installed correctly and securely to prevent leaks or bypass of contaminated fluid. Follow the manufacturer's guidelines for installation procedures and torque specifications.

Monitor Fluid Condition: Monitor the condition of the hydraulic fluid regularly and perform fluid analysis tests to detect contaminants or degradation. This can help identify potential issues early and prevent damage to system components.

By incorporating these maintenance practices into your hydraulic system maintenance routine, you can ensure that your filters continue to effectively remove contaminants and keep your system running smoothly.

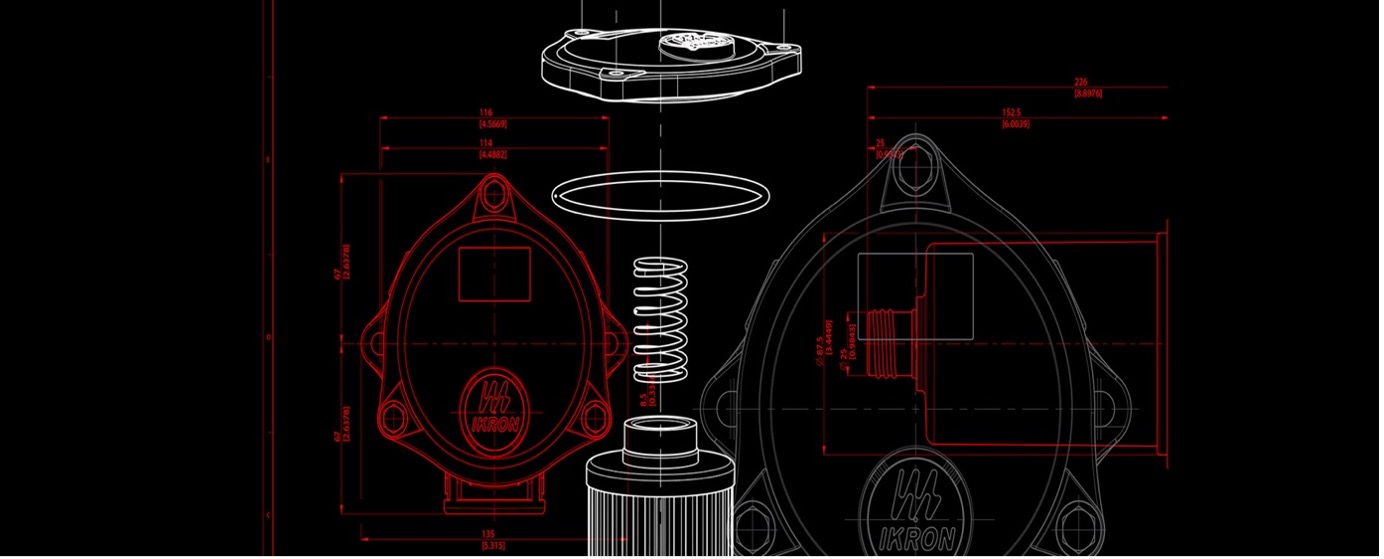

VHS Hydraulic Components is an official UK dealer for Ikron Fluid Filtration. Founded in 1997 in Italy, Ikron Fluid Filtration is part of the Casappa group and offers a range of hydraulic filtration products, including Suction Filters, Return Line Filters, Spin-On Filters, Medium Pressure Filters and High Pressure Filters, as well as a variety of accessories and reservoir components.

https://www.hydraulic-components.net/ikron

To enquire or speak to our technical team about all your hydraulic solutions and requirements please contact VHS Hydraulic Components on: 0114 276 4430 / E: info@www.hydraulic-components.net or visit our website at: https://www.hydraulic-components.net

No Minimum Order

No Minimum Order