In the realm of hydraulic systems, the importance of a reliable and efficient power pack cannot be overstated. These compact units are the heart of hydraulic machinery, providing the necessary force to drive cylinders, motors, and other components. While off-the-shelf hydraulic power packs exist, there are instances where a customized solution becomes imperative to meet specific requirements. In this comprehensive blog, we will explore the world of custom hydraulic power packs, delving into their design, applications, benefits, and the process of tailoring these systems to meet diverse industrial needs.

Understanding Hydraulic Power Packs

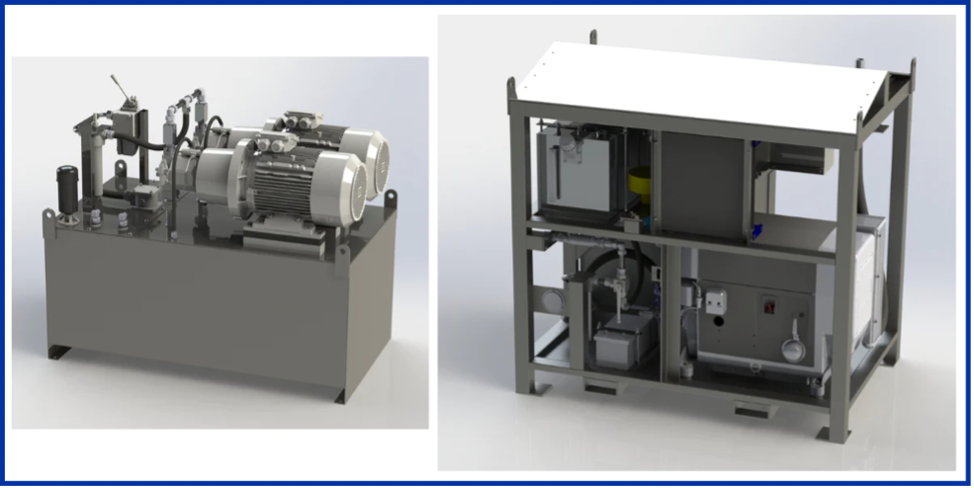

A hydraulic power pack, also known as a hydraulic power unit (HPU), is a self-contained system that generates and delivers hydraulic power to various components within a hydraulic system. It typically consists of a hydraulic pump, reservoir, motor, and other components, all housed in a compact and integrated package. The power pack is a critical element in hydraulic machinery, providing the force necessary for the operation of hydraulic cylinders, motors, and other actuators.

Applications of Hydraulic Power Packs

Hydraulic power packs find applications across a wide range of industries due to their versatility and efficiency. Some common applications include:

Industrial Machinery: Hydraulic power packs are extensively used in industrial machinery such as presses, punch machines, and plastic injection molding equipment.

Material Handling Equipment: Forklifts, scissor lifts, and other material handling equipment rely on hydraulic power packs for their lifting and maneuvering functions.

Construction Equipment: Hydraulic power packs are crucial in construction equipment, including excavators, loaders, and cranes, where they provide the necessary power for various hydraulic functions.

Agricultural Machinery: Tractors, harvesters, and other agricultural machinery often incorporate hydraulic power packs to facilitate the movement of implements and perform other functions.

Marine Applications: Hydraulic power packs are used in marine systems for steering mechanisms, hatch operations, and other hydraulic functions on ships and boats.

Customization in Hydraulic Power Packs

While standard, off-the-shelf hydraulic power packs are suitable for many applications, certain scenarios demand a customized approach. The decision to opt for a custom hydraulic power pack is influenced by specific requirements, including:

Unique System Specifications: When a hydraulic system has unique specifications, such as non-standard pressure or flow rate requirements, a custom power pack allows for precise tailoring to meet these specifications.

Space Constraints: In situations where space is limited, a custom-designed power pack can be created to fit within confined spaces while still delivering the required power.

Environmental Considerations: Customization enables the incorporation of features that address specific environmental conditions, such as resistance to extreme temperatures, corrosive environments, or compliance with specific industry standards.

Integration with Existing Systems: Custom hydraulic power packs are designed to seamlessly integrate with existing hydraulic systems, ensuring compatibility and optimal performance.

Benefits of Custom Hydraulic Power Packs

Investing in custom hydraulic power packs offers several advantages that contribute to enhanced performance, efficiency, and cost-effectiveness:

Optimized Performance: Tailoring the power pack to meet the exact specifications of the hydraulic system ensures optimal performance, reducing energy consumption and improving overall efficiency.

Space Efficiency: Custom power packs can be designed to fit within the available space constraints, maximizing the use of limited real estate in industrial settings.

Reduced Energy Consumption: By precisely matching the power pack's specifications to the hydraulic system's requirements, energy consumption is minimized, resulting in cost savings over the long term.

Enhanced Durability: Customization allows for the selection of materials and components that are best suited to the operating conditions, increasing the power pack's durability and lifespan.

Improved Integration: Custom hydraulic power packs are seamlessly integrated into existing systems, reducing the need for extensive modifications and minimizing downtime during installation.

The Customization Process

Designing a custom hydraulic power pack involves a systematic process to ensure that the final product aligns with the specific needs of the application. The customization process typically includes the following stages:

Needs Assessment: The first step is a thorough assessment of the application's requirements. This includes understanding the desired pressure and flow rates, available space, environmental conditions, and any other unique specifications.

Conceptual Design: Based on the needs assessment, engineers develop a conceptual design that outlines the overall layout, components, and specifications of the custom power pack. This design serves as a blueprint for the manufacturing process.

Component Selection: Careful consideration is given to the selection of components, including the hydraulic pump, motor, reservoir, and control valves. The chosen components must align with the performance requirements and environmental conditions of the application.

Fabrication and Assembly: Once the design is finalized and components are selected, the fabrication and assembly process begins. Skilled technicians assemble the power pack, ensuring precision and adherence to quality standards.

Testing and Quality Assurance: The custom power pack undergoes rigorous testing to validate its performance under real-world conditions. This includes testing for pressure, flow rates, temperature tolerance, and other critical parameters. Quality assurance measures are implemented to ensure reliability and durability.

Installation and Commissioning: After successful testing, the custom power pack is installed in the target system. Engineers oversee the commissioning process to ensure seamless integration and optimal performance.

Hydraulic Power Pack Manufacturer

Hydraulic power packs are not one-size-fits-all; each application has unique requirements. Therefore, designing a hydraulic power pack with the right components and fittings is crucial for optimal performance, reliability, and safety.

VHS Hydraulic Components and its sister company Neilson Hydraulics specialise in designing and manufacturing an extensive range of Hydraulic Power Units and Hydraulic Power Packs.

- We have been designing, building, installing and commissioning hydraulic power units for over 30 years, covering a wide range of applications across a variety of sectors.

- We manufacture custom-made hydraulic power units than can be built strictly in accordance with client specifications. We are able to provide you with a complete hydraulic solution from concept to completion. We can provide repeat hydraulic power units, as well as hydraulic power units for specialist projects.

- We work in a variety of industry sectors, including oil, gas, petrochemical, marine, offshore, material handling, recycling, agriculture, rail, quarrying, construction, injection moulding, steel, mining and water authority.

- We have strong technical abilities in CAD, SolidWorks, system controls and hydraulic circuit design.

Specialists in designing and building Hydraulic Power Units

- Specialists in the design, build, manufacture, installation and commissioning of hydraulic power units.

- Produce standard hydraulic power units, including budget, mid-range, medium-pressure and high pressure.

- Offer custom-made hydraulic power units to meet client specifications for specialist and repeat projects.

- Vast expertise in a variety of industry sectors.

You may also be interested in our previous blog

How does a Hydraulic Power Pack Work?

Conclusion

Custom hydraulic power packs represent a tailored approach to meet the diverse and unique requirements of hydraulic systems in various industries. The ability to customize these power packs provides numerous benefits, including optimized performance, space efficiency, reduced energy consumption, enhanced durability, and seamless integration with existing systems. The customization process, involving needs assessment, conceptual design, component selection, fabrication, testing, and installation, ensures that the final product align.

To enquire or speak to our technical team about all your hydraulic solutions please contact VHS Hydraulic Components on: 0114 276 4430 / E: info@www.hydraulic-components.net or visit our website at: https://www.hydraulic-components.net

No Minimum Order

No Minimum Order