Hydraulic power packs, also known as hydraulic power units (HPUs), play a pivotal role in numerous hydraulic systems across various industries. These compact units are capable of generating substantial power, making them indispensable for powering hydraulic machinery and equipment. In this article, we will explore the fundamentals of hydraulic power packs, their working principles, applications, key components, and the importance of proper maintenance.

What is a Hydraulic Power Pack?

Before delving into the intricacies of hydraulic power packs, let's establish a clear understanding of what they are and their primary purpose. Essentially, a hydraulic power pack is a self-contained unit designed to supply the necessary power to actuate hydraulic components within a hydraulic system, such as hydraulic motors or cylinders. These power packs are essential for applications demanding high power levels that cannot be achieved using integrated power sources alone.

One of the notable advantages of hydraulic power packs is their portability. They come in various sizes and configurations to meet specific application requirements, and their ability to operate without direct access to a fixed power source makes them highly versatile.

How Is Hydraulic Power Unit Required Power Calculated?

Hydraulic power is defined as flow multiplied by pressure. The hydraulic power supplied by a pump is: Power = (P x Q) ÷ 600 - where power is in kilowatts [kW], P is the pressure in bars, and Q is the flow in litres per minute. ** based upon 100% efficiency; 90% efficiency would equate to 75 ÷ 0.9 = 83.3kW.

How Does a Hydraulic Power Pack Work?

At its core, a hydraulic power pack harnesses the principles of hydraulic fluid dynamics to transfer energy from one point to another. This process aligns with Pascal's law, which asserts that an increase in pressure applied to a confined fluid will be transmitted uniformly throughout the fluid, ultimately transferring force to the opposite end of the container.

When this energy reaches its destination, such as a hydraulic motor or cylinder, it drives the force necessary to move the components responsible for machine operation. The hydraulic power pack serves as the energy source for facilitating these actions and can generate substantial power through either rotary or linear motion. The amount of power produced is regulated and maintained by various components within the power pack.

Components of a Hydraulic Power Pack

A well-designed hydraulic power unit possesses distinct features tailored to its intended functions. Some standard design components include:

- Accumulators: These containers, attached to hydraulic actuators, collect hydraulic fluid from the pump and maintain fluid pressure to supplement the motor pumping system.

- Motor Pumps: Hydraulic power units can feature a single motor pump or multiple devices, each with its accumulator valve. In multiple pump systems, typically only one pump operates at a time.

- Filters: Positioned along the tank's top, filters are self-contained bypass units equipped with their own motor, pump, and filtration components. They can fill or empty the tank by activating a multi-directional valve. Filters are often replaceable while the power unit is operational.

- Coolers and Heaters: These components help regulate temperature. Air coolers can prevent temperatures from exceeding operational parameters, while heaters, such as oil-based heaters, elevate temperatures when necessary.

- Power Unit Controllers: These units serve as operator interfaces, featuring power switches, displays, and monitoring capabilities. They are essential for installing and integrating power units into hydraulic systems, usually wired into the power unit.

- Pressure Supply & Relief Lines: Pressure supply lines transport pressurised fluid to the pump, while pressure relief lines serve to relieve pressure and control the flow direction.

- Hydraulic Reservoir: This container holds the hydraulic fluid and must have adequate space to accommodate fluid expansion and air removal.

Hydraulic Power Pack Maintenance

Regular maintenance is vital to ensure the smooth and safe operation of hydraulic power packs. Adhering to a maintenance schedule helps identify potential issues early, extending the unit's lifespan. Maintenance tasks include checking tubing and connections, changing hydraulic fluid, and inspecting the reservoir for corrosion or cracks.

Hydraulic Power Pack Manufacturer

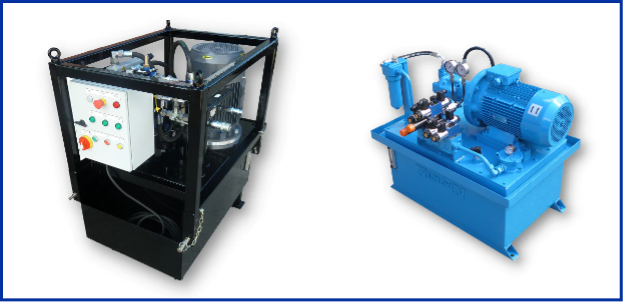

Hydraulic power packs are not one-size-fits-all; each application has unique requirements. Therefore, designing a hydraulic power pack with the right components and fittings is crucial for optimal performance, reliability, and safety.

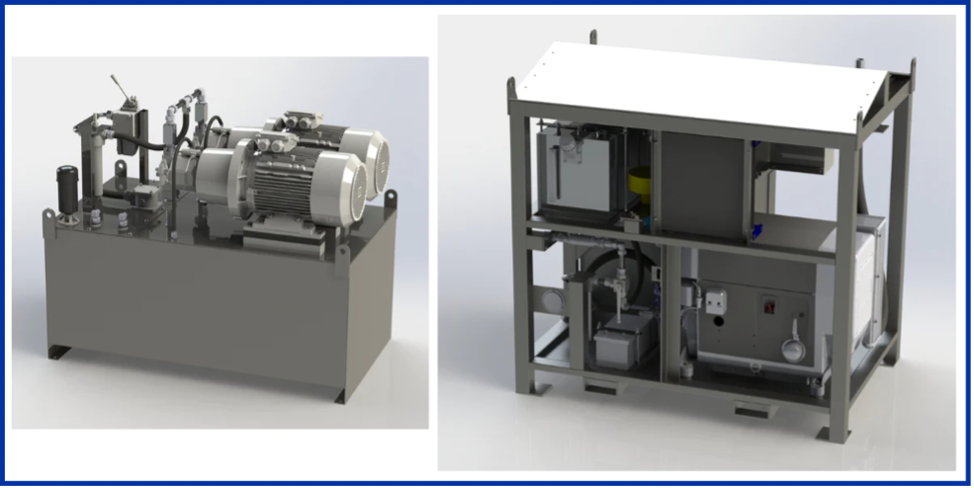

VHS Hydraulic Components and its sister company Neilson Hydraulics specialise in designing and manufacturing an extensive range of Hydraulic Power Units and Hydraulic Power Packs.

- We have been designing, building, installing and commissioning hydraulic power units for over 30 years, covering a wide range of applications across a variety of sectors.

- We manufacture custom-made hydraulic power units than can be built strictly in accordance with client specifications. We are able to provide you with a complete hydraulic solution from concept to completion. We can provide repeat hydraulic power units, as well as hydraulic power units for specialist projects.

- We work in a variety of industry sectors, including oil, gas, petrochemical, marine, offshore, material handling, recycling, agriculture, rail, quarrying, construction, injection moulding, steel, mining and water authority.

- We have strong technical abilities in CAD, SolidWorks, system controls and hydraulic circuit design.

Specialists in designing and building Hydraulic Power Units

- Specialists in the design, build, manufacture, installation and commissioning of hydraulic power units.

- Produce standard hydraulic power units, including budget, mid-range, medium pressure and high pressure.

- Offer custom-made hydraulic power units to meet client specifications for specialist and repeat projects.

- Vast expertise in a variety of industry sectors.

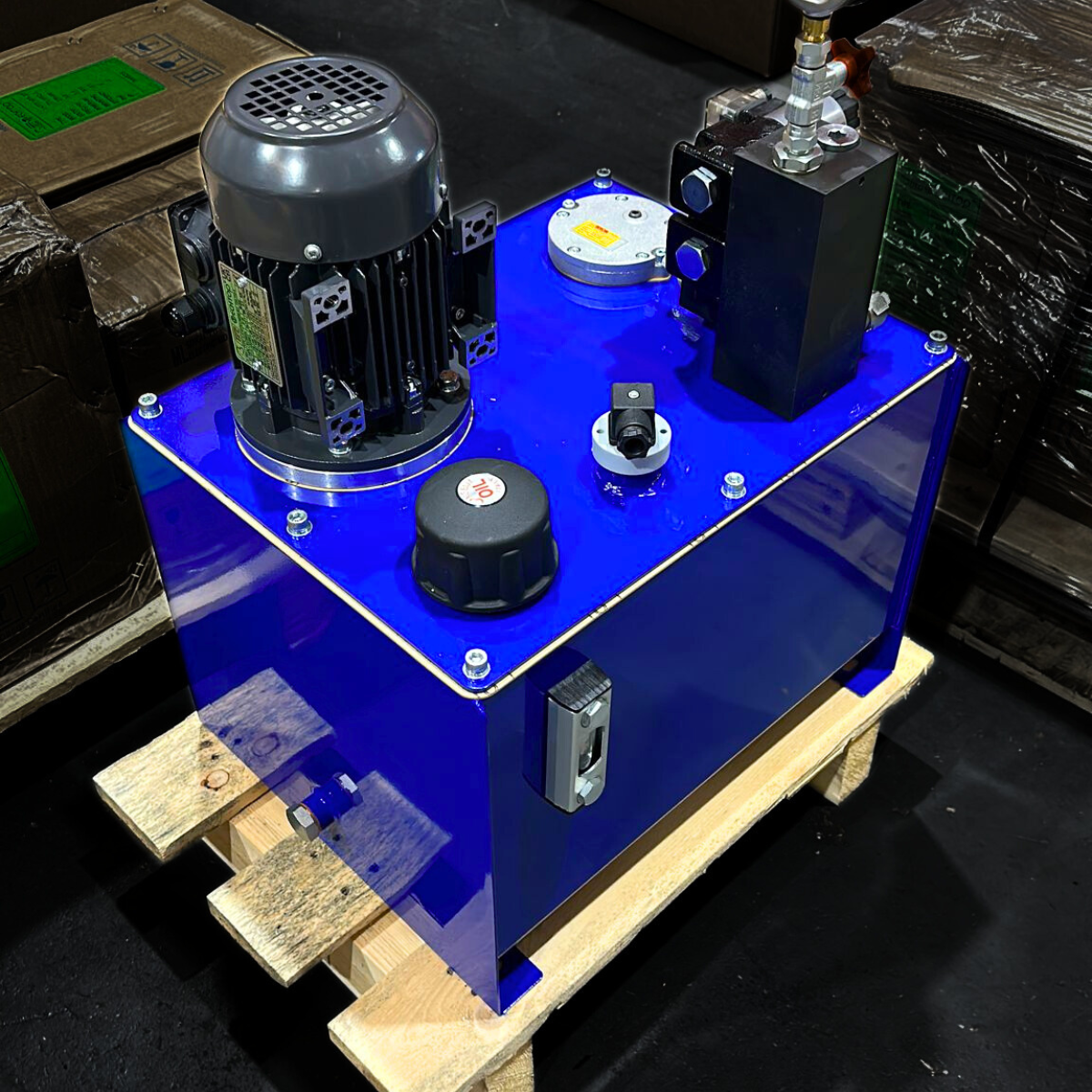

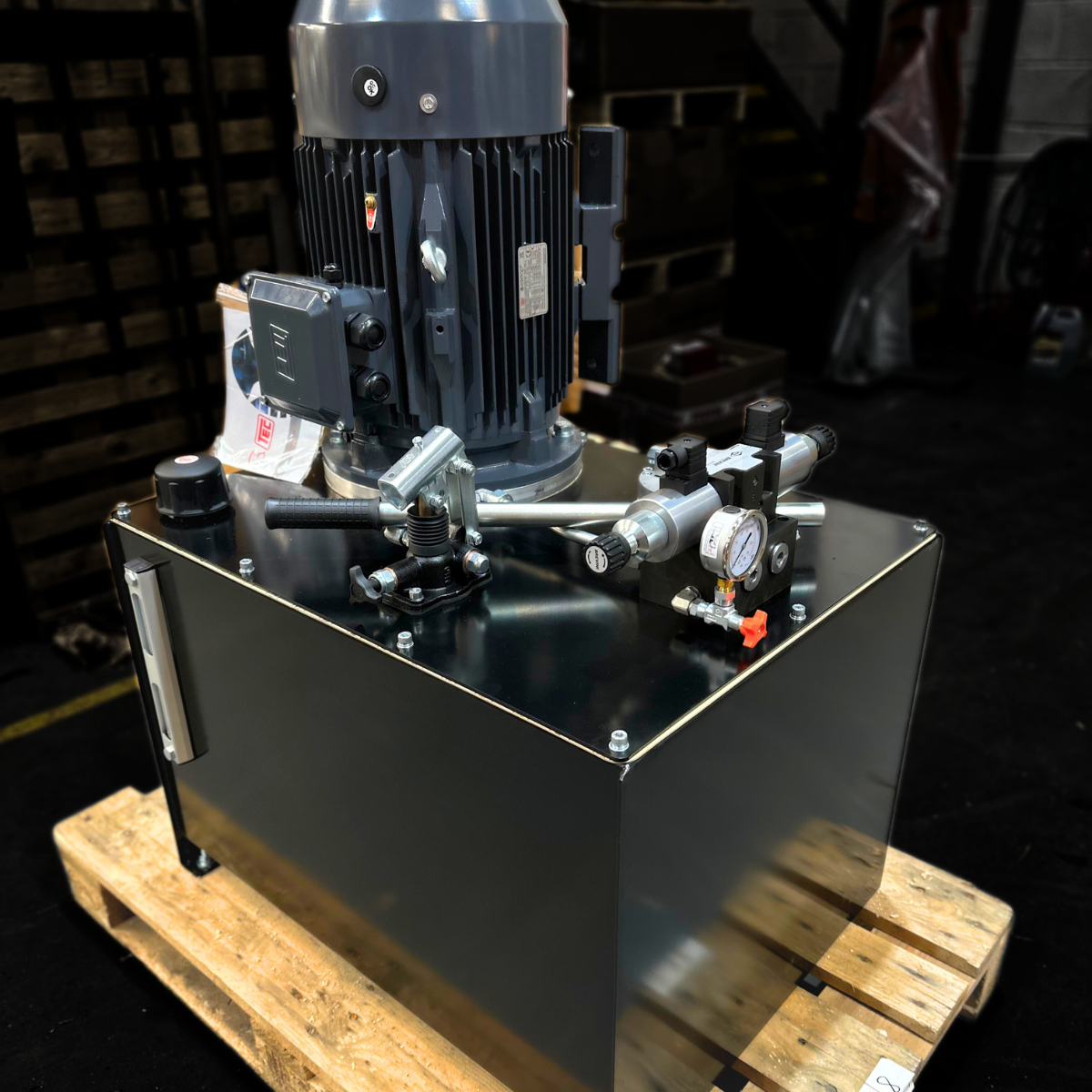

22Kw Powerpack

3Kw Bespoke Powerpack

15Kw Powerpack

We also offer our own standard range of hydraulic power units, including:

Budget range

- Mid-range

- Medium Pressure range

- High Pressure range

- Hydrostatic Closed Loop range

To enquire about your hydraulic power pack requirements and talk to our experts, please contact VHS Hydraulic Components on: 0114 276 4430 / E: info@www.hydraulic-components.net or visit our website at: https://www.hydraulic-components.net.

No Minimum Order

No Minimum Order