The 2 main types of hydraulic accumulators are Diaphragm and Bladder-type accumulators. A hydraulic accumulator is a pressure vessel that performs many tasks in a hydraulic system. They are used to maintain pressure, store and recapture energy, reduce pressure peaks, power chassis suspensions, and dampen shock, vibration and pulsations.

General information

One of the main tasks of hydro-pneumatic accumulators is e.g. to accept certain volumes of pressurised liquids of hydro-pneumatic installations and to return them to the system if required.

As the liquid is pressurised, the hydro-pneumatic accumulators are treated like pressure vessel and must be designed for the max. operating over pressure considering the acceptance standards of the country of installation.

In most hydro-pneumatic systems, hydro-pneumatic accumulators with separator element are used. The difference between bladder-type, piston and diaphragm-type accumulators lies in the type of separator element.

Hydro-pneumatic accumulators essentially consist of a fluid section and a gas section with a gas-tight separator element. The fluid section has a connection to the hydraulic circuit. During the pressure increase, the gas is compressed and liquid accepted in the hydro-pneumatic accumulator. When the pressure decreases, the compressed gas expands and displaces the accumulated fluid into the circuit.

Bosch Rexroth Diaphragm Type Accumulators (HAD)

▪ Component series 1X and 2X

▪ Nominal capacity 0.075 … 3.5 L

▪ Maximum operating pressure 250 bar

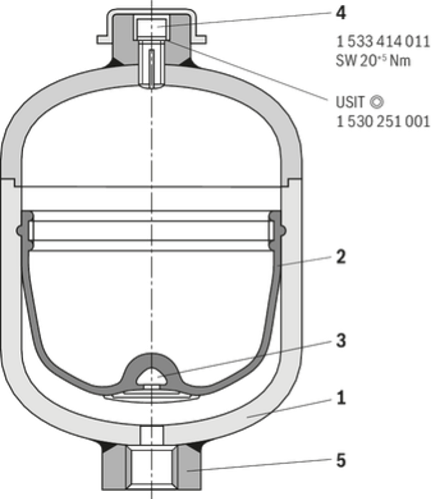

Diaphragm type accumulator

Diaphragm-type accumulators consist of a pressure resistant steel vessel (1) which most commonly has a spherical to cylindrical form. Inside the accumulator, there is the separator element, namely a diaphragm (2) made of an elastic, flexible material (elastomer) with the closing button (3) and the plug screw (4). They correspond to Pressure Equipment Directive 2014/6 8/EU.

Bosch Rexroth Bladder Type Accumulators (HAB)

- Component series 6X

- Nominal capacity 1 … 50 l

- Maximum operating pressure 350 bar

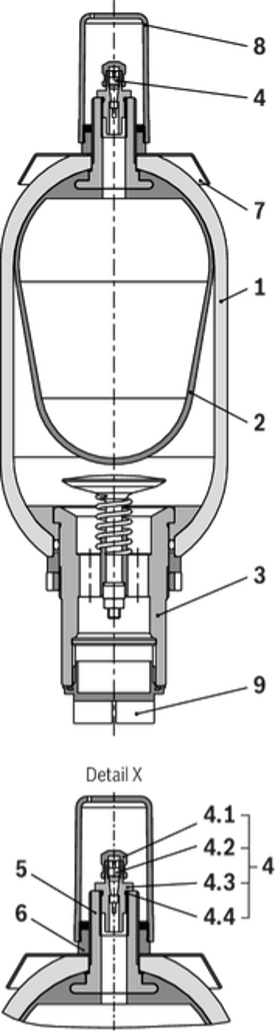

Bladder-Type Accumulator

Bladder-type accumulators consist of a seamless cylindrical pressure container (1) made of high-strength steel. An elastic bladder (2) mounted inside the container separates the accumulator into a gas side and a fluid side.

Via the gas valve (4), the bladder is filled with nitrogen up to the intended gas filling pressure p0.

The oil valve (3) located inside the oil port of the bladder-type accumulator closes if the pressure on the gas side is higher compared to the fluid side. This prevents the bladder from entering the oil channel and being destroyed.

When the minimum operating pressure is reached, a small fluid volume (approx. 10% of the hydraulic accumulator's nominal volume) should remain between the bladder and the oil valve in order to prevent the bladder from hitting the valve during each expansion process.

The gas valve (4) consists of sealing cap (4.1), gas valve insert (4.2), gas prefill valve body (4.3), and O-ring (4.4). These parts can be replaced individually. The type cap (7) includes the technical data and features of the hydraulic accumulator.

We are a Bosch Rexroth Certified Excellence Partner

To enquire or speak to our technical team about all your hydraulic requirements, please contact VHS Hydraulic Components on: 0114 276 4430 / E: info@www.hydraulic-components.net or visit our website at: https://www.hydraulic-components.net

No Minimum Order

No Minimum Order