IMO Slewing Rings have been impressing the construction machine sector for more than 25 years with their robustness, long service life and reliability. Slewing Rings are large diameter antifriction bearings for the simultaneous transmission of axial and radial forces as well as tilting moments. They replace traditional solutions with fixed and floating bearings as well as king pin bearings. Frequently, this results in bearings with axial/radial bearing combinations with one bearing point. This can significantly simplify the design of the mounting structure and the installation of the bearings, which in turn reduces effort and costs.

What construction machines are IMO Slewing Rings typically used for?

- Excavator attachments

- Wheel loader

- Asphalt vibratory rollers

- Landfill compactors

- Drilling rigs

Cost-effective and tried-and-tested, IMO Slewing Rings are available as:

- Ball slewing rings, roller slewing rings, and ball-roller combination slewing rings

- Four-point bearings, double four-point bearings/eight-point bearings, flange bearings, wire race bearings, cross roller bearings

- Segmented slewing rings

- Gear rims

- External gearing, internal gearing, or without gearing

- Diameter ranging from 100 mm to 6000 mm

- With cages (steel, brass, or plastic) or spacers (brass or plastic)

- With standard seals or specially produced special seals

- Optionally with induction-hardened raceways

- Different corrosion protection coatings possible

For companies operating in the construction industry, IMO Slewing Rings provide a variety of benefits including:

For purchasing:

- Focus on cost-efficient solutions

- Delivery times you can rely on

- Fast reaction times

For engineering:

- Impact and vibration-resistant

- Customer-specific versions

- Special seals to protect from dirt and coarse particles

For service:

- Reduced servicing costs

- Long Service Life

- Service and spare parts available worldwide

For end customers:

- Tailor-made sturdy solutions

- High levels of operational safety

- Highest level of resilience

- Low overall costs

Below are a couple of examples of the IMO Slewing Ring being utilised in the construction environment that it was expertly designed for.

*IMO Slewing Ring for construction example 1.

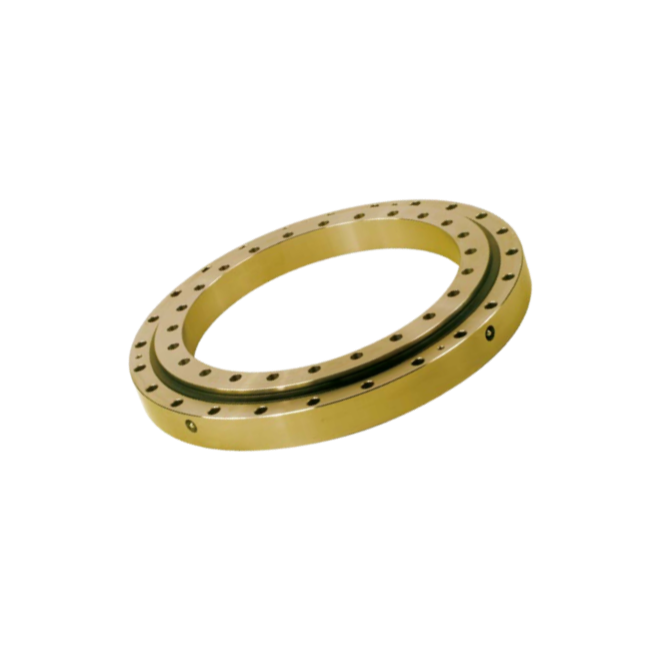

IMO Ball Slewing Ring flange, for a wheel loader.

*IMO Slewing Ring for construction example 2.

Vibratory rollers such as landfill compactors with surface-coated IMO Slewing Ring in the knuckle joint.

VHS Hydraulic Components is proud to be an official IMO UK distributor. We have a highly experienced technical team available to help and discuss your requirements and provide you with solutions. Please view https://www.hydraulic-components.net/imo-slewing-rings for further information on IMO Slewing Rings but also contact VHS Hydraulic Components on: 0114 276 4430 / E: info@www.hydraulic-components.net.

VHS Hydraulic Components is an IMO UK distributor. VHS Hydraulic Components supplies IMO Slew Drives, including IMO Slew Drives WD Series (WD-L & WD-H) and IMO Slew Drives SP Series (SP-I & SP-H), as well as IMO Slewing Rings, including IMO Ball Slewing Rings, IMO Roller Slewing Rings and IMO Ball-roller Combination Slewing Rings.

No Minimum Order

No Minimum Order